Table of Contents

The Bhopal disaster occurred on December 3, 1984, in Bhopal, India, when 45 tons of toxic methyl isocyanate gas leaked from a pesticide plant owned by Union Carbide. The gas spread over nearby neighborhoods, killing thousands instantly and causing panic as tens of thousands tried to escape. The death toll was between 15,000 and 20,000, with half a million survivors suffering from respiratory problems, eye issues, and other health problems.

The Bhopal Gas Leak Tragedy: Union Carbide’s Lethal Chemical Disaster

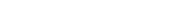

The Union Carbide factory, built in 1969, produced the pesticide Sevin using methyl isocyanate (MIC) as a key ingredient. The process created MIC, which was then used to make carbaryl. Despite low demand for pesticides, production continued, leading to the accumulation of unused MIC in underground tanks.

In the 21st century, over 400 tons of toxic waste remained at the site. Both the Indian government and Dow Chemical, which bought Union Carbide in 2001, failed to clean it. The contamination caused ongoing health issues, including birth defects. In 2004, India’s Supreme Court ordered clean drinking water for Bhopal residents. In 2010, several Union Carbide India executives were convicted of negligence.

The Bhopal Gas Leak Tragedy: Uncovering the Worst Industrial Disaster in History

The Union Carbide India Limited (UCIL) plant, part of India’s Green Revolution, was a 50.9% subsidiary of Union Carbide Corporation. It was fully operated by Indian workers and located in Bhopal. The plant produced pesticides using methyl isocyanate (MIC), a highly toxic substance. MIC is more dangerous when inhaled than ingested, and it vaporizes at room temperature, making it colorless and odorless. This causes eye irritation and throat discomfort. The Occupational Safety and Health Administration (OSHA) exposure limit is just 0.02 ppm over an 8-hour period. MIC also reacts violently with water, releasing dangerous heat and potentially causing a runaway reaction.

Previous Warnings & Accidents:

Six accidents occurred before the catastrophe.

- 1981: One worker died from phosgene gas exposure.

- 1982: 24 workers exposed to phosgene.

- 1982: Engineer burned by MIC.

- October 1982: Operator suffered severe burns while fixing a valve leak.

December 2, 1984:

- 8-9 PM: MIC plant supervisor ordered to wash several pipes from the phosgene system to the scrubber through the MIC storage tanks.

- 9:30 PM: Water washing begins; a bleeder valve (overflow device) was blocked.

- 11 PM: Control room operator noticed the pressure gauge on Tank E610 rose from 2 psi to 10 psi.

- 11:30 PM: Workers noticed MIC’s smell and saw a leak near the scrubber.

- 12:15-12:30 AM: Control room operator saw the pressure indicator for Tank E610 read 25-30 psi.

- 12:40 AM: Plant supervisor turned on in-plant and external toxic gas sirens; operators turned on the fire water sprayer.

- 1 AM: Plant supervisor realized spare tank E619 was not empty, preventing pressure reduction in E610.

- 1:30 AM: Bhopal police chief informed of the leak; no significant police mobilization followed.

- 8 AM: The Madhya Pradesh governor ordered the plant’s closure and the arrest of the plant manager and four other employees.

The Release:

- Water entered V-610, starting a polymerization reaction.

- The tank contents were initially at ambient temperatures and the reaction progressed unchecked due to a lack of cooling.

- The heat from the reaction boiled the MIC monomer, releasing 54,000 lbs of MIC.

Contributing Factors:

Human Error:

- A critical isolation valve wasn’t closed before pipes were flushed with water, causing fatal pressurization.

- The flare for neutralizing escaping gas was shut down.

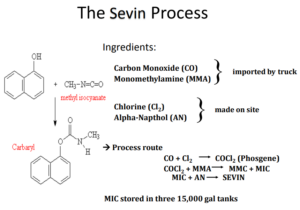

Inadequate Safety Equipment:

- The sprayer’s reach for neutralizing gas was inadequate, and plant managers were aware of the deficiency.

- The flare system couldn’t handle a major gas leak.

Failure of Safety Equipment:

- The stack scrubber activated during the leak failed.

Poor Maintenance:

- Tank refrigerators were inoperable due to drained freon.

- Pipes meant to drain water that pressurized the tank were blocked.

Inadequate Staffing:

- Union-Carbide-trained supervisors had left Bhopal by 1984.

- Staffing in the MIC unit was cut to below recommended levels.

- The second-shift maintenance supervisor position was eliminated weeks before the disaster.

Lack of Evacuation Plans:

- Union Carbide engineers had stressed the need for an evacuation plan, but UCIL claimed to have one, while city and state officials were unaware of it.

Inadequate Response:

- The warning siren was activated briefly.

- Public response was panicked, with a slow and uncoordinated evacuation.

- Medical workers were hampered by a lack of information about MIC.

Investigation:

- The New York Times reported that a large volume of water entered tank 610, causing the accident (“Water Washing Theory” – Employee violated policy and failed to use a slip blind).

- Union Carbide also cited water entering tank 610 but suggested possible sabotage by a disgruntled employee.

- The Indian Government’s findings were similar to the New York Times.

The Bhopal Gas Leak Aftermath: Lasting Impacts on Health, Environment, and Community

The gas leak killed an estimated 25,000 people in a short time.

- Long-term Health Impact: People born after 1985 in Bhopal face higher risks of cancer, disabilities, and lower educational achievements.

- Water Pollution: Water sources near the factory became contaminated, and many handpumps were sealed due to unsafe drinking water.

- Displacement: Many people were forced to evacuate the area because of fears of another gas leak.

- Food Scarcity: People living near the factory had to discard their food due to contamination fears.

Aftermath of the Bhopal Gas Leak: Compensation, Legal Struggles, and Regulatory Changes

In 1985, the Indian government passed the Bhopal Gas Leak Disaster (Processing of Claims) Act to help settle claims. Union Carbide agreed to pay $470 million in compensation, but there were complaints about delays in distributing the funds.

- Charges Against Officials: Charges were filed against Union Carbide’s chairman and other officials, but they were released on bail and never punished.

- Post-Disaster Measures:

- Environment (Protection) Act, 1986: This law gave the government the power to regulate industrial activities for public and environmental safety and strengthened pollution control.

- Public Liability Insurance Act, 1991: This law provided insurance to offer immediate relief to people affected by accidents involving hazardous substances.

TSPSC Group 1 Question Paper 2024, Downl...

TSPSC Group 1 Question Paper 2024, Downl...

TSPSC Group 1 Answer key 2024 Out, Downl...

TSPSC Group 1 Answer key 2024 Out, Downl...

UPSC Prelims 2024 Question Paper, Downlo...

UPSC Prelims 2024 Question Paper, Downlo...